top of page

FUSION

DESFROSTING

TECHNOLOGY

FUSION TECHNOLOGY

When a food is thawed, the surface ice layer melts into a layer of liquid water whose thermal properties are lower than those of solid-state water.

As a consequence, and due to the speed with which heat is transferred into the food, this insulating effect increases as the defrosted food layer increases.

That is why the defrosting of a food, for the same temperature gradient, is slower than its freezing.

Cellular damage caused by slow freezing and recrystallization causes the loss of cellular components, which manifests itself in the form of an exudate through which various compounds of nutritional value are lost.

SENSITIVE

HEAT

It is the heat energy supplied to a body or an object, which increases its temperature without affecting its molecular structure, that is, it does not change phase.

The name comes from the opposition to latent heat that refers to the "hidden" heat, that is to say that a temperature increase is supplied but not "perceived" as in the phase change from ice to liquid water and from this one to steam.

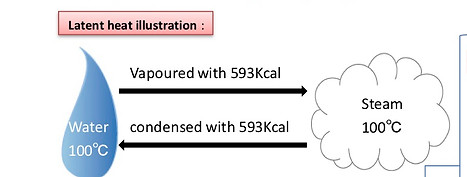

LATENT

HEAT

It is the energy required by an amount of substance to change phase, from solid to liquid (heat of fusion) or from liquid to gas (heat of vaporization). Sensitive heat is perceived, since it increases the temperature of the substance, causing it to be perceived as "hotter", or on the contrary, if heat is subtracted, it is perceived as "colder".

The FUSION defroster defrosts the frozen food using the condensed latent heat of 539 Kcal / kg.

This latent heat is generated when steam is sprayed on its surface from -20 ° C to 0 ° C to transform it into drops of water.

By using the great energy of latent heat, faster defrosting occurs with adequate humidity, being more efficient, with better performance and of higher quality, avoiding loss of color and flavor.

The latent heat of condensation occurs when steam is converted into water.

The blown steam becomes a drop of water in contact with defrosting (frozen food) from 20 ° C to 0 ° C.

At that time, given the amount of close heat of 586 kcal / kg. to products to be defrosted (20 ° C), they are defrosted without losing quality and reducing operating costs thanks to the shorter time spent.

DESCONGELADOR FUSION BF-3215

ADVENTAGES OF DEFROSTING

FUSION

ONLY USE LOW TEMPERATURE STEAM

DEFROST GREAT QUANTITY ONCE

LOWER COST FOR LOW WATER CONSUMPTION

GREATER UNIFORMITY DUE TO THE VARIABLE WIND SYSTEM

NO RISK OF PRODUCT TEMPERATURE INCREASE

REDUCE MICROBIAL GROWTH

VERY FAST

BETTER QUALITY BY DRIP ELIMINATION

LOW DEHYDRATION

OF THE PRODUCT

PREVENT WATER HEATING WITH A 3 STAGE PROGRAM

POSSIBILITY OF STORAGE

OF THE DEFROSTED PRODUCT

.jpg)

DESCONGELADOR BF-3215

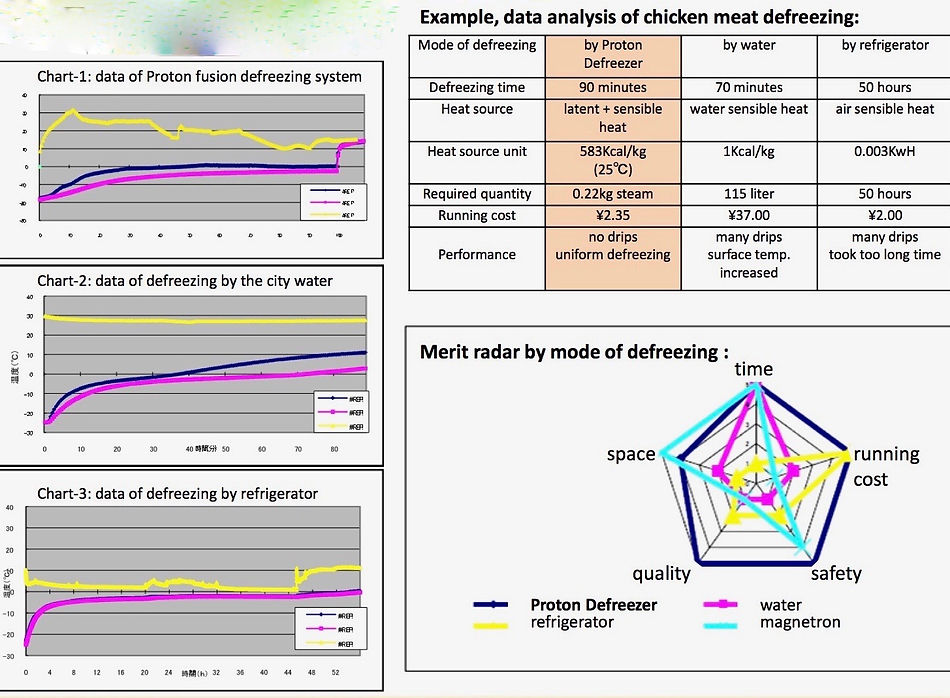

COMPARATIVE

DEFROSTING METHODS

EXAMPLE OF

DEFROSTING

CHICKEN MEAT DEFREEZING

DESCONGELADOR BF-3215

bottom of page