top of page

PROTON

MAGNETIC FREEZER TECH

PROTON® technology, distributed by INNOVAFISH, is based on a combination of:

La tecnología PROTON® distribuida en exclusiva por INNOVAFISH esta basada en una combinación de:

Magnetics fields

+ Electric waves

+ Cold air

The determining factor in the organoleptic quality of the frozen product is the crystals size that form when they pass from the fresh to the frozen state.

Large crystals created by freezing with current technologies, cause cell breakage and irreparable cell damage that are manifested at the time of defrosting through the loss of exudates (liquids) that lead to changes in the original organoleptic qualities

of food.

The solution of this problem has come thanks to the use of electromagnetic fields in freezing (as in medicine with the magnetic resonances).

Thanks to them, the foundation of our technology is the ordering of the water molecules that are formed in the freezing process.

CURRENT FREEZING

PROTON TECH

The differences between a frozen food with current technologies and the same frozen food with PROTON ® are evident.

Exudates (liquid or drip) when defrosting not only contain water but also synthesize all the negative effects caused by poor freezing: the loss of nutrients (vitamins, proteins, minerals, fats and hydrates).

TECNOLOGIA DE CONGELACION MAGNETICA PROTON

¿WHAT IF WE HAVE FROZEN FOOD BADLY ALL OUR LIVES WITHOUT KNOWINGIT?

Increasingly, the media confirm that current freezing technologies modify the organoleptic and nutritional properties of foods thus frozen.

I mean

PROTON®, leading technology in Japan and the Asian continent since 2005, has solved this problem giving rise to a new product category: "frozen fresh food".

PROTON® makes it no longer possible to distinguish between a fresh food and a previously frozen thawed food with PROTON®.

Only the PROTON® technology uses freezing magnetic fields that order the water molecules in the food, preventing the expansion of the crystals and the subsequent cell breakage, which is what happens with the freezing technologies existing up to now.

ARTICULO publicado en

LA VANGUARDIA

18/02/2020

download versión

ESPAÑOL

Click to read full article

download ENGLISH version

DIFFERENCE BETWEEN PROTON AND ULTRACONGELATION

DON´T CONFUDE PROTON

WITH THE CAS SYSTEM

CAS

On the internet there are some articles that refer to the magnetic freezing system, but all of them are based on tests carried out with the ABI CAS system, precursor of this technology.

Although CAS is also based on electromagnetic principles, PROTON represents an advance in magnetic freezing technology.

The foundation of CAS freezing, manufactured by ABI, is based on the generation of low frequency vibration in the water molecules that make up the food. CAS works on the simple principle that water molecules cannot be added if they are in continuous motion during the freezing process, using rotating electric fields to spin the water molecules.

PROTON ®, manufactured by RYOHO FREEZE SYSTEMS CO. LTD., Takes advantage of the magnetic fields to order the water molecules minimizing the ice crystals produced in the cells when they freeze, leaving behind the simple vibration of CAS.

PROTON represents the latest generation of freezers.

CAS SYSTEM

MOVEMENT OF THE

MOLECULES

OF WATER

ORDER OF THE

MOLECULES

OF WATER

ARCHAIC TECHNOLOGY

NEW GENERATION

PROBLEMS OF CURRENT FREEZING

PROTON® technology manages to solve all the problems that arise from the current freezing systems:

CRYSTAL SIZEThe expansion of the volume of ice crystals occurs when slow freezing is performed. |  CELLULAR DESTRUCTIONFree water freezes producing crystals that grow, increasing its volume and destroying the cell structure. |  CONGELACIÓN EXTERIORLos métodos criogénicos congelan inicialmente la capa superficial que provoca un retraso en la congelación interior debido a esa capa congelada cristalizada con hielo en la capa superficial |

|---|---|---|

ELIMINATION OF OXYGENWith cryogenic methods, the oxygen around the product cannot be completely eliminated, and especially in the case of meat and fish, since the hemoglobin and myoglobin contained in your blood are converted by thawing into methemoglobin and methamoglobin, which causes your color differs from fresh product |  LOW DEHYDRATIONDehydration leads to weight loss, and therefore, of the value of the product, and also reduces the thermal conductivity of the surface layer influencing the texture, color and cooking time of the product |  COLOR LOSSFreezing affects the color of defrosted food, through the loss of pigments due to drip loss, and due to ice crystals a concentration of solutes occurs in the remaining fraction without freezing, which causes oxidation and darkening enzymatic |

NOT FREEZABLE PROD.Appropriate and specific freezers should be used to handle fragile or delicate products and products, a priori, difficult to freeze, such as rice, vegetables and some types of soft fruits |

PROTON ADVANTAGES

With PROTON® technology you will gain advantages in the following fields:

CLICK ON EVERY ADVANTAGE TO KNOW MORE

Today, PROTON technology is present in the lives of the Japanese through companies that freeze their products with PROTON or with frozen products and distributed by our manufacturer RYOHO FREEZER, which can be found in supermarkets, specialty food stores or in "konbinis" (コ ン ビ ニ) or convenience stores, open 24 hours a day, 7 days a week.

See the following link for some of the examples:

PROTON range

The capacity of the PROTON® range is measured per Kg. Frozen per hour.

In Europe, we have freezers that freeze from 3 kg to 500 kg per hour...

To know the equipment that best suits your needs, we should know the time needed for your product to freeze.

VERY IMPORTANT

It must be taken into account that we always talk about capacity NOMINAL capacityand not of actual capacity.

The REAL capacity should be calculated based on the time the food needs to freeze.

For example, if it is a food that requires 15 min. to freeze, such as the sushi, we must calculate 4 freezing cycles in 1 hour (15 min.x 4 = 60 min.) so to calculate the real capacity of the model, we must also multiply x 4 (in this case) its nominal capacity.

For this example, and in case we were calculating the real capacity of the PF-15 to freeze sushi, its real capacity is 60 kg / hour, discounting the loading and unloading times between each freezing cycle.

|  |

|---|---|

|  |

|  |

PROTON CUSTOMERS

PROTON® is marketed in Japan since 2005.

However, both in Europe and in America, we started marketing it from the year 2020 exclusively on these two continents.

In this short period of time, prestigious companies that seek the highest quality in the freezing of their products have relied on PROTON magnetic freezing technology.

These are some of our most prominent clients:

expansion

PROTON EXPANSION

The expansion of PROTON® continues in Europe, but especially in the Americas, where we have recently reached an agreement to establish PROTON CENTROAMERICA, with headquarters in Nicaragua and Costa Rica.

Soon, we hope to present PROTON SOUTH AMERICA.

We are looking for potential partners for the US markets (PROTON USA) and in the Persian Gulf (PRONTON MIDDLE EAST).

PROTON CENTROAMERICA

GRUPO MEDICA NICARAGUA, S. A. MANAGUA (NICARAGUA) D. LUIS ADOLFO GABUARDI RODRÍGUEZ Tel.+50585524289 lagabuardi@grupomedica.net

PROTON ISRAEL

ARIE SRUGO CONSULTING & PROJECTS ADI (ISRAEL) Mr. ARIE SRUGOT Tel.+972 54 9080144 srugoa@gmail.com

PROTON PERU

PATRONATO GASTRONOMICO DEL PERU SANTIAGO DEL SURCO (PERU) Mr. MARCO ANTONIO SANCHEZ Tel.+51 975173976 marcosanchez57@gmail.com

PROTON MEDICAL

MEDICO

In addition to the food sector, PROTON® is a technology widely used in Japan in the medical sector, especially used in the field of regenerative medicine for the freezing of artificial cells, including IPS cells.

To this end, we have launched the PROTON MEDICAL division to meet the freezing needs of this sector.

PROTON MEDICAL

Congelación en el sector médico y farmacéutico.

PROTON MEDICAL

Ms. MERCE MENCHON Tel.+34639925473 merche@innovafish.com

PROTON HEALTH

Freezing aims to extend the shelf life of food while maintaining its original organoleptic qualities.

None of the current freezing technologies can ensure that the quality of a food will remain unchanged after going through a freezing and thawing process, with the importance that any change in a food can affect our health.

The maintenance of all the original organoleptic properties of food as well as the elimination of the population of bacteria and their reproduction, the death of microorganisms and parasites such as anisakis in the products of the sea, the inhibition of the activity of the most resistant pathogens and especially, the conservation of nutrients, have an unquestionable impact on health, allowing their long-term storage without additives and complying with full guarantees the legal health regulations.

Frozen food producers as well as establishments with services to the public (restaurants, catering, hotels, etc.) should always keep in mind the incidence of a good freeze on the products they offer.

The advantages provided by PROTON® in terms of quality and sanitary safety mean that freezing & health go together for the first time.

SUSTAINABLE PROTON

REDUCTION FOOD RESIDUES

Food is lost or wasted throughout the supply chain, from initial production to final household consumption. The decline may be accidental or intentional, but ultimately leads to less food availability for everyone.

According to FAO, the total cost of food loss and waste is one billion dollars, about 700 billion in environmental costs and about 900 billion in social costs.

Food waste is responsible for 8% of global greenhouse gas emissions.

In addition, the reduction of food waste plays an important role in favoring the circular economy and combating water scarcity in the world.

Thanks to PROTON® freezing technology, food waste losses can be reduced by being able to organize production in advance, reduce or eliminate waste and take advantage of leftovers.

In addition, PROTON® is a clean technology (only uses electric current, magnets and cold air) without using additional gases (nitrogen, etc.) that affect the environment.

DEFROSTING

DEFROSTING TECHNOLOGY

FUSION

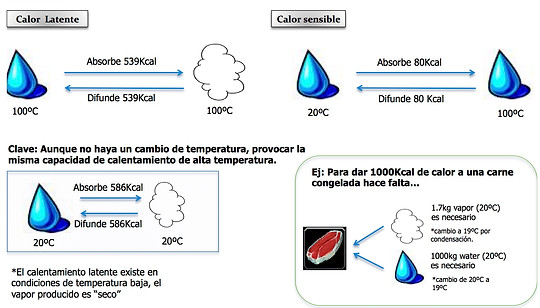

The FUSION defroster defrosts the frozen food using the condensed latent heat of 539 Kcal / kg.

This latent heat is generated when steam is sprayed on its surface from -20 ° C to 0 ° C to transform it into drops of water.

By using the great energy of latent heat, faster defrosting occurs with adequate humidity, and more efficient, with better performance and of the highest quality, avoiding loss of color and flavor.

PERFECT FREEZING with the

FULL CYCLE

PROTON

FREEZING

FUSION

DEFROSTING

TV JAPON NOTICIAS SOBRE PROTON

FOR A SUSTAINABLE DEVELOPMENT

bottom of page